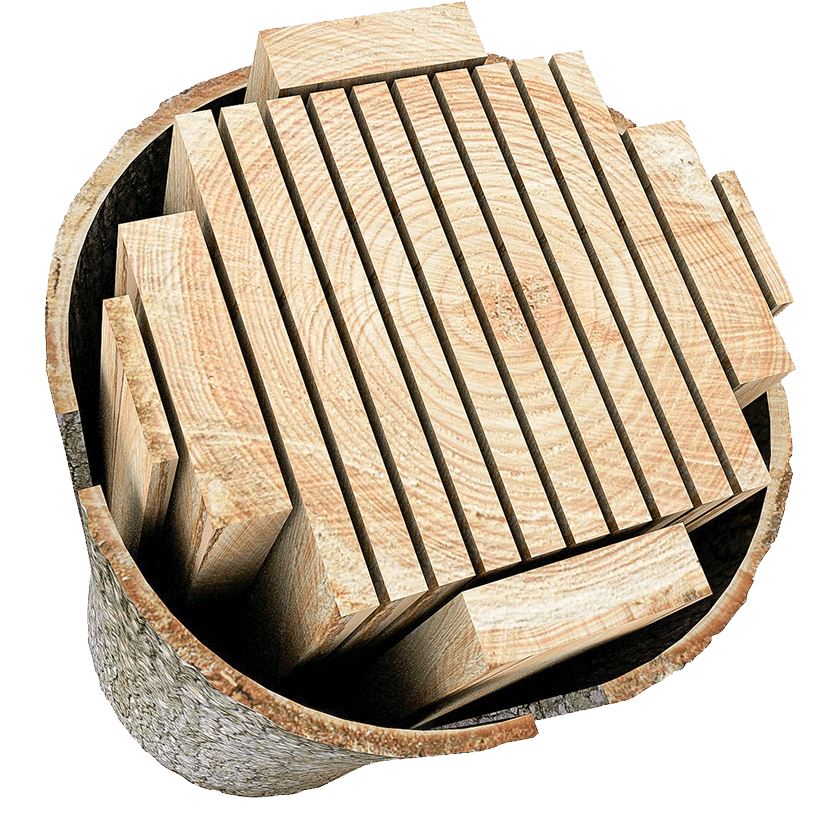

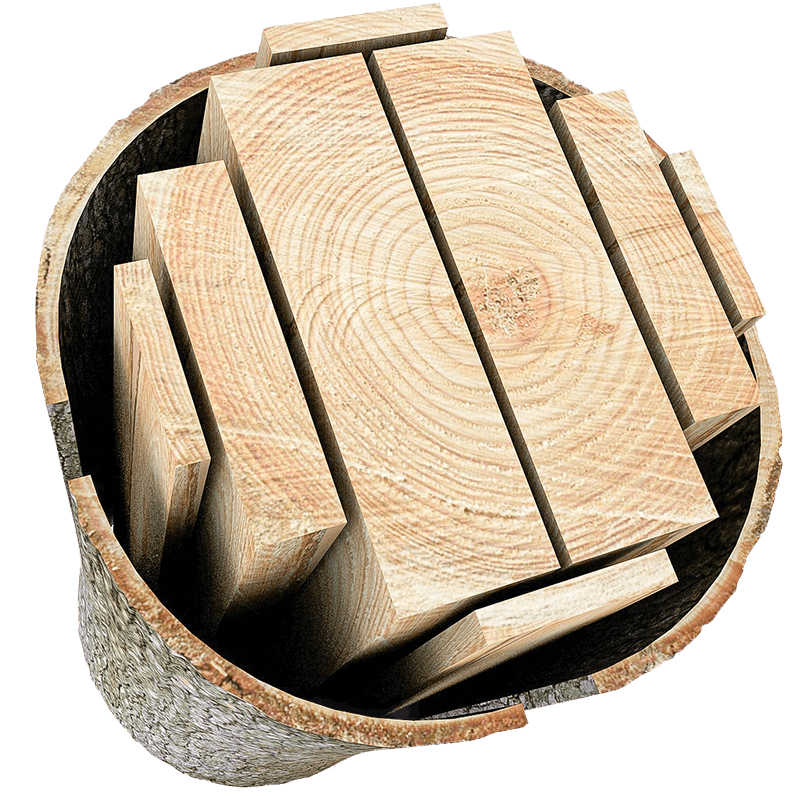

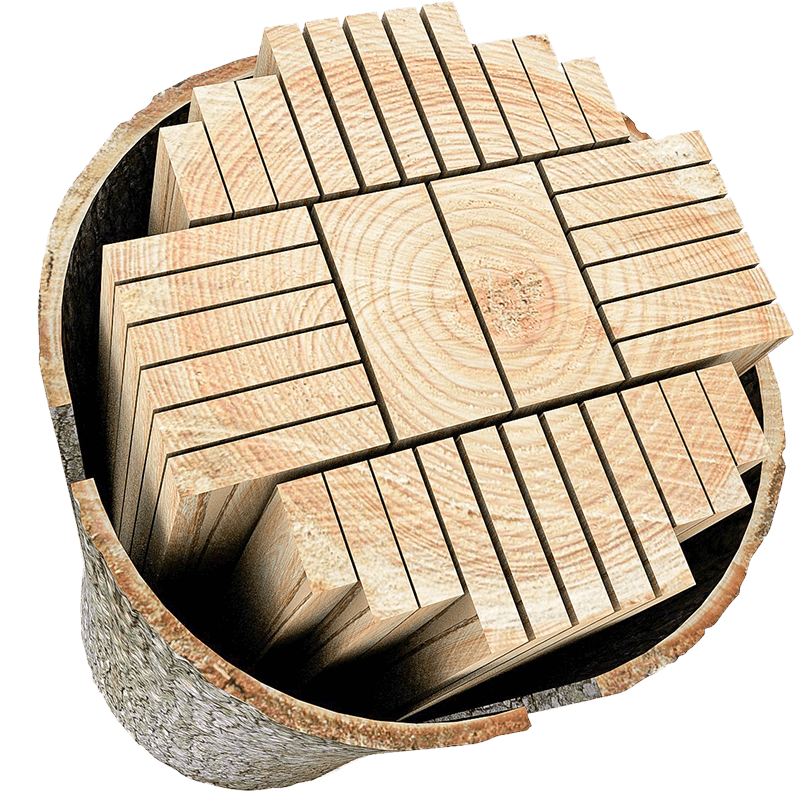

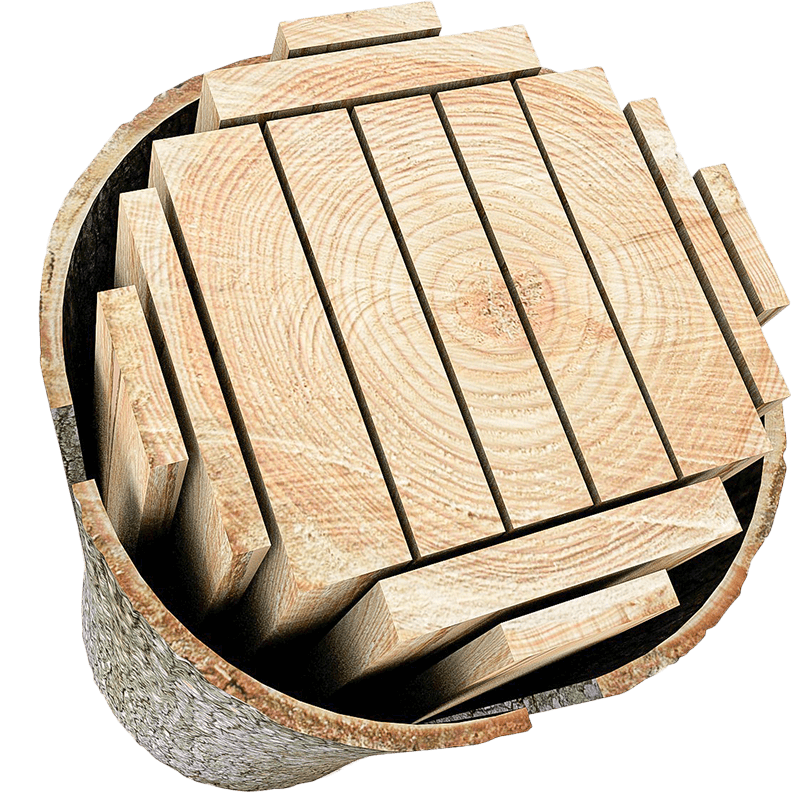

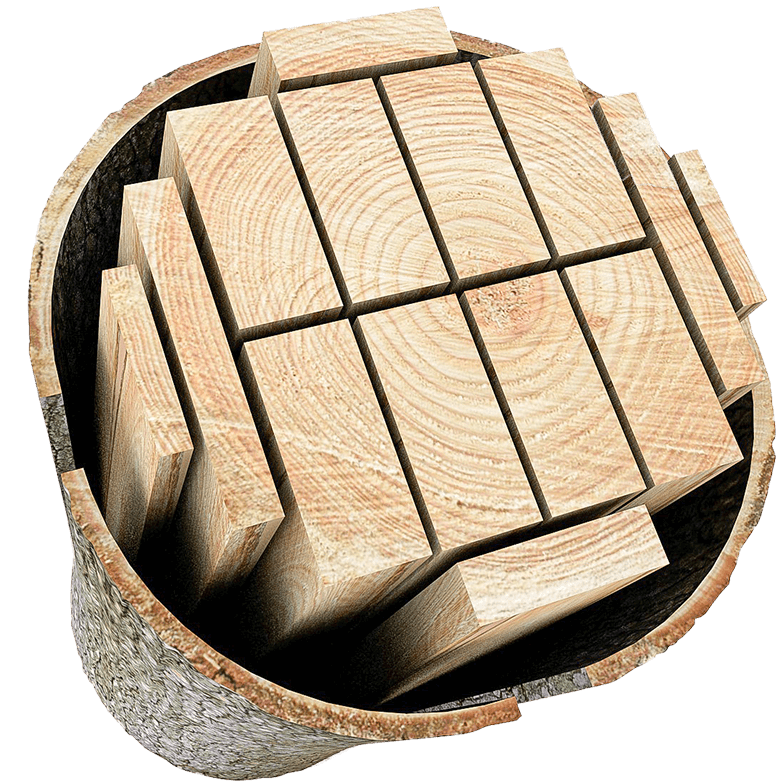

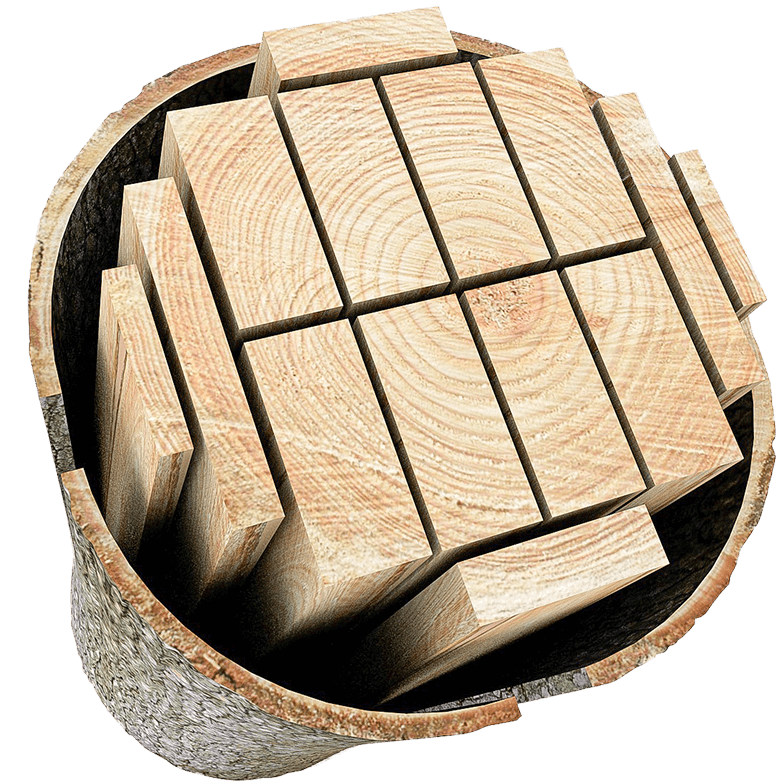

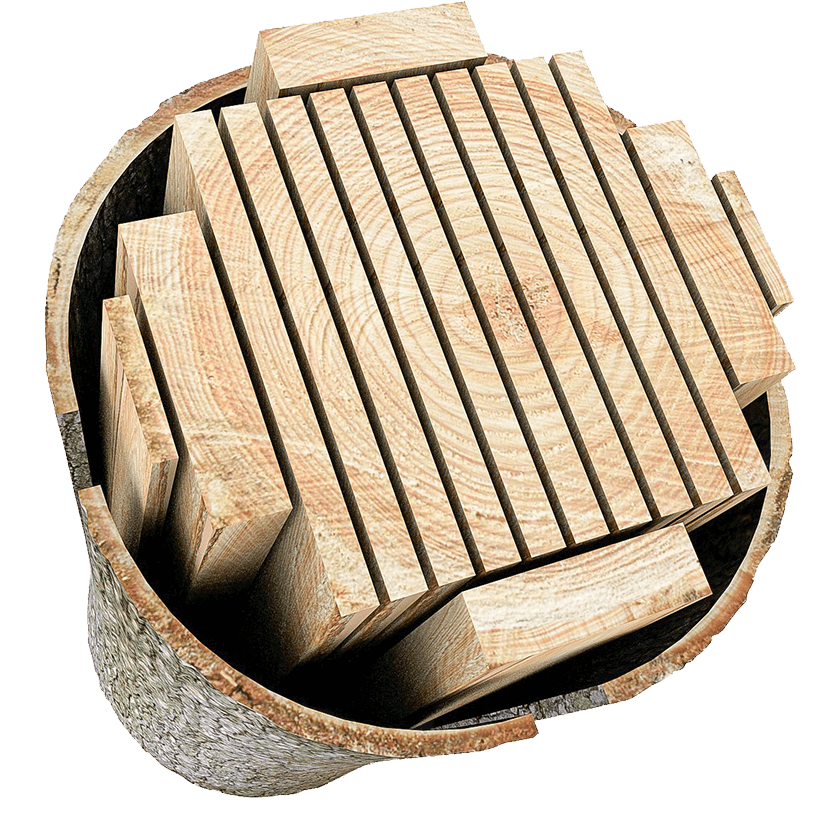

Sawn timber

Using state-of-the-art chipper and circular saw technology, the pre-selected logs are processed into an extensive range of sawn timber. Gentle technical drying, tailored to the respective product, ensures a target and application-oriented wood moisture content.

Our product range includes:

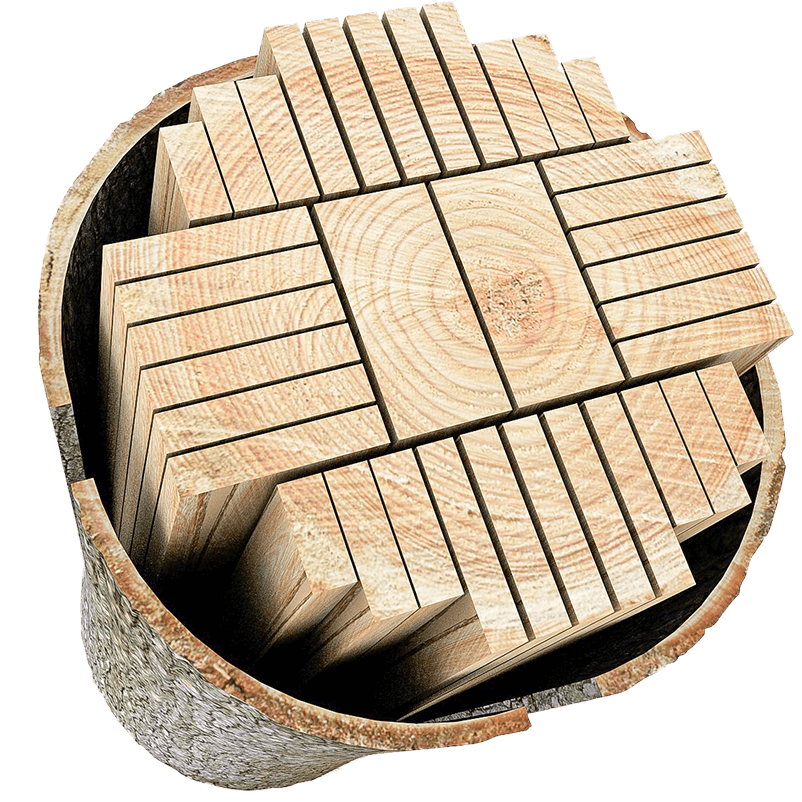

- Lamellas for glulam and cross laminated timber

- Lamellas for laminated beams, core-separated or core-free

- Raw materials for window scantling manufacturers

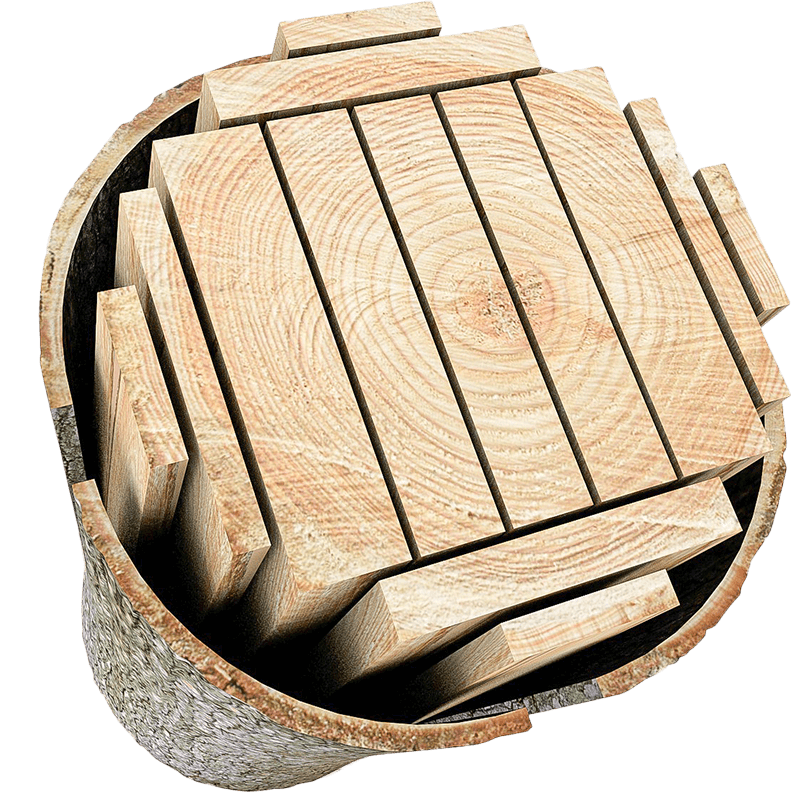

- Various dimensions rough sawn for structural interior and exterior timber construction

- Center boards ready for planning

- Slats, battens and posts as building materials or construction aids

- Morali

- Side boards for industrial processing (parquet, floorboards, strips, etc.)

- Side boards for the packaging industry

Grading in accordance with Austrian timber trade practices, individual agreements and guidelines as well as EN 14081 for strength-graded timber

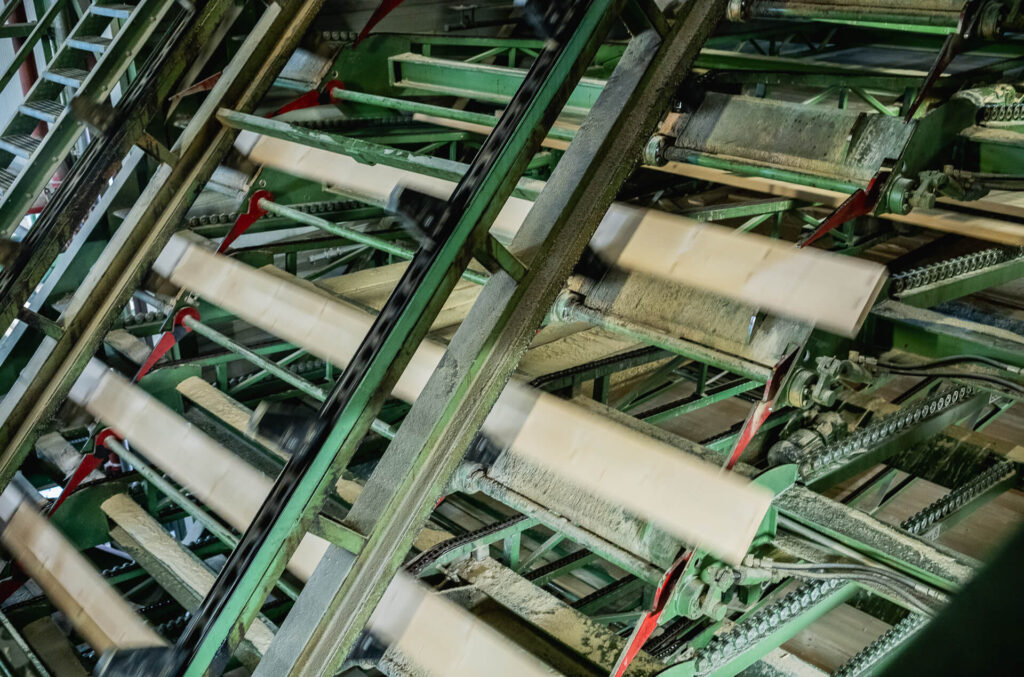

Precision with advanced circular saw technologies

Johann Offner Holzindustrie sets itself apart with its advanced circular saw technologies, which make it possible to realize unique cutting patterns. This specialty allows us to respond to specific customer requirements with individually adapted wood products.

Technical specifications and capacities

Cross-sectional spectrum

Thicknesses from 12 mm to 145 mm

Widths from 75 mm to 295 mm

Standard lengths up to 4.00 m

Drying capacities

up to 400,000 m³ of wood

Incision technology

Our modern profiling hogging line and circular hogging saw line enable precise and efficient processing for the highest product quality.

Technical specifications sawn timber

| Wood species | Spruce (Picea Abies) |

| Standard length | 4 m |

| Thickness | 12 mm – 145 mm |

| Width | 68 mm – 300 mm |

| Length | 3000 mm – 4000 mm |

| Wood moisture | Drying according to standard moisture content or customer-specific requirements 8 – 20 % Goods also available fresh |

| Grading | according to the Austrian Timber Trade Standards (ÖHHU) according to EN 14081-strength grading, by agreement and guidelines |

Residual wood

In the course of our sawn timber production, we also produce high-quality residual wood products such as chips, which result from the latest chipper and circular saw technology. These wood chips are an important by-product of our production and are used in a variety of industrial applications.

Our range of waste wood products includes:

- Wood chips for paper and bioenergy

- Sawdust for the chipboard industry and pellet producers

- Bark for fuel and mulch

Each waste wood product is carefully processed and sorted to maximize its use in various industrial applications.

Transportation and logistics

Johann Offner Holzindustrie benefits from an excellent logistics infrastructure that guarantees fast and efficient transportation options. Thanks to the direct connection to the rail network and the close access to the highway at Wolfsberg Nord, we are able to ship our products in the shortest possible time. In addition, our connections to the international ports in Koper, Trieste and Rijeka facilitate the global export of our timber products. This strategic location enables us to react flexibly and quickly to customer requirements, both nationally and internationally.